Why Is My Ground Source Heat Pump So Expensive to Run? Uncovering the Key Factors

As green buildings and clean heating solutions gain popularity, ground source heat pump systems have attracted significant market interest due to their energy-saving and environmental benefits. However, many users are discovering that actual operating costs far exceed expectations – here’s what’s behind the numbers.

The adoption of ground source heat pump systems continues to grow as sustainable building practices become increasingly important. Yet despite their theoretical efficiency, numerous users report unexpectedly high operating expenses.

This phenomenon stems from a combination of factors including high initial investment, system design limitations, geological considerations, and operational strategies. This article provides an in-depth analysis of the reasons behind these costs and offers professional solutions.

1 The Mystery of High Operating Costs

During periods of extreme summer temperatures, more ground source heat pump owners are confronting substantial operating expenses. While theoretically considered a high-efficiency energy-saving technology, why do so many users complain about excessive electricity bills?

In reality, operating costs are influenced by multiple factors: system design, geological conditions, operational strategies, and maintenance quality. Understanding these elements is essential for identifying effective ways to reduce expenses.

2 Balancing Initial Investment and Operating Costs

Ground source heat pump systems typically require significantly higher upfront investment than conventional AC systems. Industry data indicates that a standard residential system can cost over 100,000 CNY, several times more than traditional central air conditioning.

The primary cost driver is the ground loop system installation. Adequate heat exchanger piping must be buried underground to absorb energy, requiring the drilling of 50-130 meter deep boreholes.

At current labor rates, drilling costs range from 70-100 CNY per meter. A 400-square-meter villa might require 10 boreholes at 100 meters each, adding 70,000-100,000 CNY to the total cost.

3 The Impact of Geological Conditions

Local geology critically affects operational efficiency. Geological variations between different regions – and even adjacent plots – directly influence ground loop heat exchanger performance.

When construction encounters special geological conditions such as caves or fractured zones, drilling equipment must be adjusted, increasing labor costs. These unpredictable factors ultimately impact operating expenses.

4 Thermal Imbalance Issues

Systems in southern regions face a particular challenge: dddhhhthermal imbalance.dddhhh Summer cooling loads typically exceed winter heating demands in these areas, causing continuous heat rejection into the ground and gradually increasing underground temperatures.

This problem reduces cooling efficiency during summer months, raising operating costs. As the system operates over years, heat accumulation worsens, causing expenses to rise annually.

Research shows that continuous operation can cause soil temperature changes exceeding 6°C over 10 years, while intermittent operation (daily shutdowns) limits temperature changes to 2.8°C and improves cooling efficiency by 2°C.

5 System Design and Equipment Selection

System design directly impacts operating costs. Most domestic ground source heat pump providers are equipment manufacturers who supply units without comprehensive system design, resulting in efficient equipment within inefficient systems.

The lack of complete national standards for product manufacturing and application technology, along with insufficient evaluation systems and market access mechanisms, contribute to poor system energy efficiency.

6 Operational Strategies and Maintenance Management

Operational approaches and maintenance standards significantly impact costs. Studies demonstrate that appropriate operational strategies can dramatically improve system efficiency.

Intermittent operation (daily shutdowns) controls heat accumulation through high-frequency thermal recovery, stabilizing output water temperature at 23.01-11.73°C with 35% reduced fluctuation. While 90% of temperature recovery occurs within the first month of shutdown, long-term imbalance creates a dddhhhthermal memorydddhhh effect in the soil.

At Yantai North Station in Shandong Province, optimizing system operation by connecting intake and output water across three heat pump units achieved annual savings of approximately 113,000 CNY in operating costs.

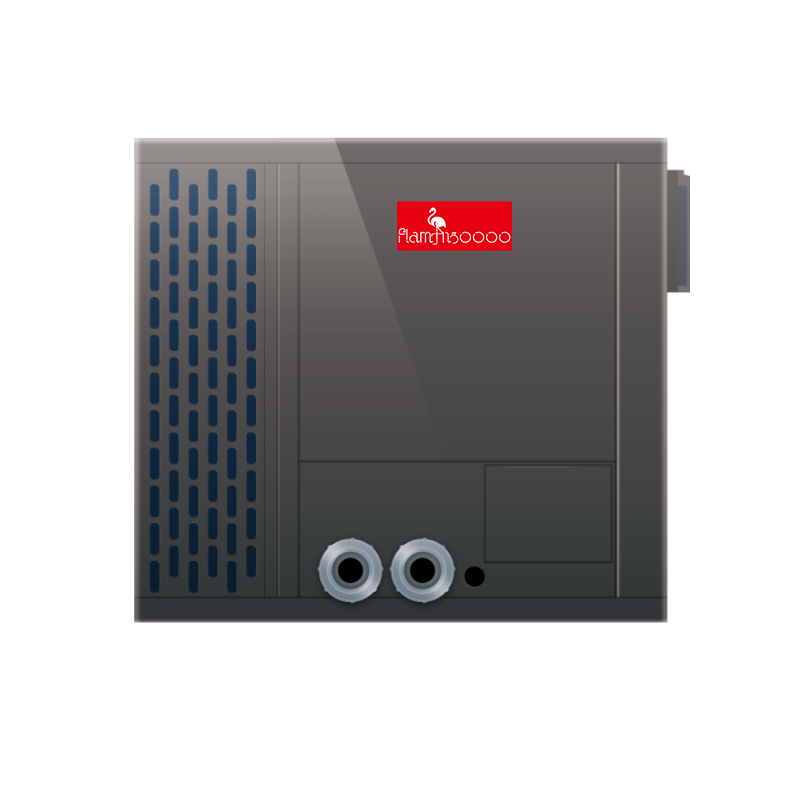

7 Technological Innovations and Solutions

Technological advances continue to address high operating costs. Magnetic levitation ground source heat pump units represent one such innovation.

China's first magnetic levitation unit, implemented in Weifang's Geological Home Community, demonstrated real-time maximum energy savings of 53.4%, with overall electricity savings exceeding 30%.

Combined deep and shallow system applications offer another innovative solution. Professor Li Jianlin's team at North China University of Technology addressed low heating efficiency in severe cold regions by implementing combined systems at Changchun Modern Logistics Center.

Through intelligent control systems optimizing coordinated operation between deep and shallow systems, comprehensive COP reached nearly 4, with operating costs of approximately 12-18 CNY/square meter – significantly below municipal heating prices.

Dynamic digital twin modeling, introduced in 2025, uses IoT technology to collect real-time operational data, employing multi-objective optimization algorithms to dynamically adjust equipment parameters and optimize energy efficiency.

8 Professional Recommendations and Future Outlook

To address high operating costs, users should conduct thorough preliminary assessments during system design, including geological surveys, load calculations, and system simulations.

Select experienced system integrators rather than simply purchasing equipment, ensuring overall system performance rather than just unit efficiency. Given the importance of operational strategies, implement intelligent control systems that automatically adjust operation based on load changes and electricity pricing.

Regular system maintenance and performance testing helps identify and resolve issues promptly, preventing efficiency degradation.

As technology advances and industry standards improve, operating costs are expected to decrease further. Applications of digital twin and artificial intelligence technologies will enable smarter operation and higher efficiency optimization.